Heidelberg

Sheetfed Offset

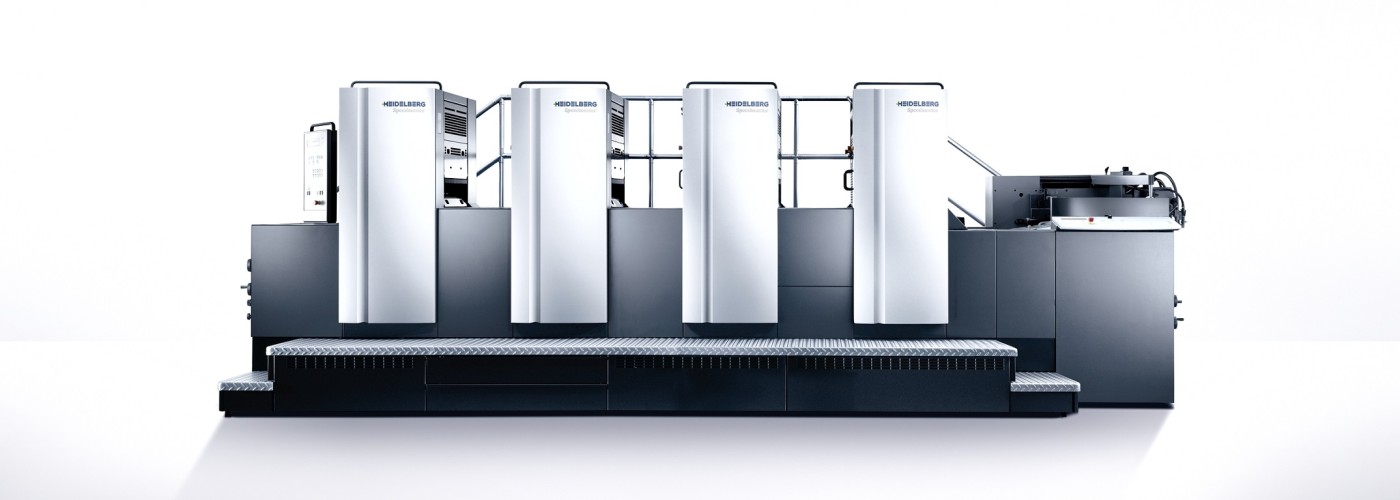

The Speedmaster CD 102 is the universal straight-printing press for commercial, packaging and label printing. Equipped with innovative technology, it provides flexible processing of a large variety of jobs and materials with maximum flexibility. Its efficiency and cost effectiveness cannot fail to impress. Easy to use, with short makeready times and integration in the Prinect workflow, the Speedmaster CD 102 achieves constantly high print quality at speeds of up to 15,000 sheets an hour. An attractive price/performance ratio is not the only advantage of the Speedmaster CD 102. Its strengths are obvious in the production of specialized packaging in up to seven colors, for example, and in UV and coating applications. Another plus: each Speedmaster CD 102 is backed up by the comprehensive service offering from Heidelberg. This enables you to get the most from your machine at all times thanks to maintenance, remote functions, perfectly coordinated consumables, and an international service and spare parts network

The Speedmaster CS 92 is tailor-made for commercial print jobs in DIN format. It therefore offers you a solution with the best possible price/performance ratio, for the cost-effective production of brochures, catalogs and flyers. Gain an advantage over the competition. Benefit from 20 percent cheaper printing plates than the 70 × 100 cm (27.56 × 39.37 in) format

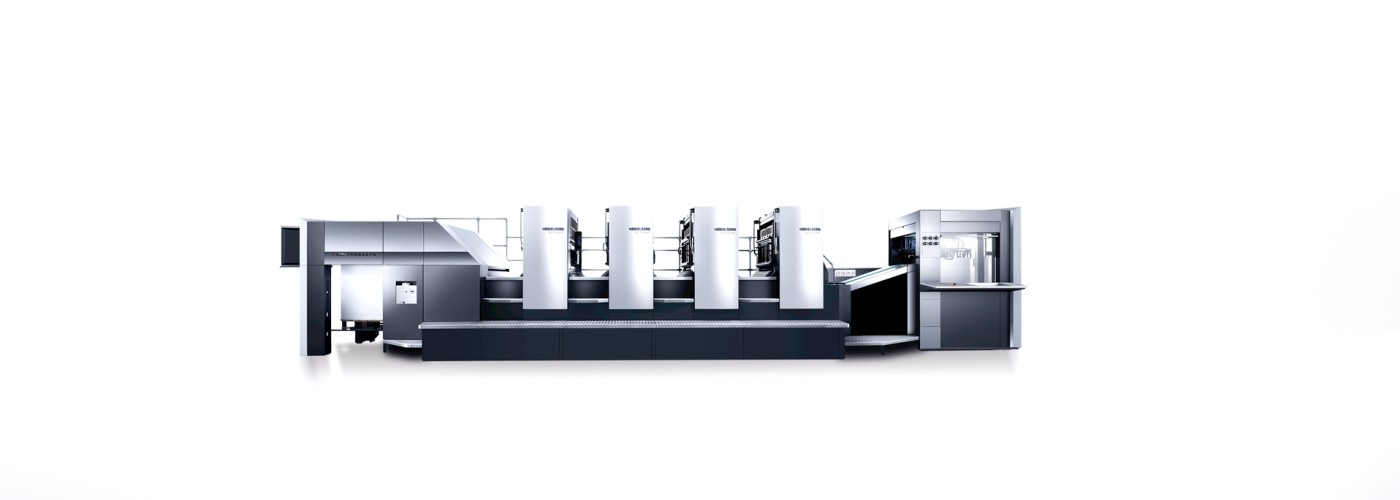

The Speedmaster CX 102 offers a modern press concept that combines the reliability of the CD series, tried and tested with well over 100,000 printing units installed worldwide, and the most innovative technology of the Peak Performance class. The Speedmaster CX 102 is the universal straight-printing press in 70 × 100 format. With speeds of up to 16,500 sheets per hour, there are very few challenges in commercial, label, and packaging printing that it cannot handle, and no customer requirements that it cannot meet. The perfect interaction of all components enables the Speedmaster CX 102 to easily process all materials from lightweight paper through to rigid cardboard.

The Speedmaster SX 52 is one of a kind in A3 format. Equipped with the latest technology, and tried and tested with over 40,000 units sold, it provides an alternative way for print shops to compete with web-to-print and digital printing. Open up new markets: the Speedmaster SX 52 sets standards whether with UV technology for premium finishing treatments, with the Anicolor short inking unit for short production runs and minimal paper waste, or as an eight-color or perfecting press.

Application-oriented equipment packages at attractive terms: this is the USP of the special edition models of the Speedmaster SX 52. Available with two or four printing units for traditional commercial printing, they combine Speedmaster quality with equipment details precisely tailored to our customers’ needs.

The Speedmaster SX 74 is our reliable solution for the medium-size format range for economical printing of traditional print jobs like brochures and advertising mailers. Equipped with the latest technology, it provides flexible processing of different production run lengths. Invest in a press that is both powerful and proven: with short makeready times, printing speeds of up to 15,000 sheets per hour, and optionally with coating unit, perfecting press, or UV technology, the Speedmaster SX 74 is designed for high productivity at all times.

Application-oriented equipment packages at attractive terms: this is the USP of the special edition models of the Speedmaster SX 74. Available with two or four printing units for traditional commercial printing, they combine Speedmaster quality with equipment details precisely tailored to our customers’ needs.

The Speedmaster SX 102 is our perfecting press that combines the reliability of the tried and tested SM series with the most innovative technology of the Peak Performance class. More than 35,000 users worldwide use the Speedmaster perfecting technology as an instrument for their success. The Speedmaster SX 102 is the perfect investment in the future for commercial printers, publishers, and web-to-print print shops. The perfecting press in 70 × 100 format offers dependably high output in straight printing and perfecting with speeds of up to 14,000 sheets per hour. The precision of our unique perfecting technology and the outstanding sheet travel ensure consistently high quality on both sides, even with very thin substrates.

Our Speedmaster XL 75 is the result of development geared entirely towards our customers’ needs. This future oriented press in 50 × 70 format delivers top efficiency, maximum productivity, and total ease of operation – for the greatest possible success without any compromises. The Speedmaster XL 75 offers you extensive configuration options for the most demanding requirements in commercial, label, and packaging printing. The result is a customized press, designed for your success in the market. Get the jump on industrial printing production of tomorrow with Push to Stop: for the first time in the history of offset printing, you can now change jobs fully automated – from the last to the first good sheet, right up until production starts. The patented process- and job-oriented assistance system Intellistart 2 will revolutionize how you change jobs, with efficient job preparation and automatic generation of time-optimized job change programs.

The Speedmaster XL 75 Anicolor 2 permits fast, flexible, and economical production of short runs in commercial, packaging, and label printing, and in so doing is the next evolution in our successful and proven Anicolor technology. The Anicolor 2 inking unit consists of a single-speed screen roller with ink chamber blade. It is not necessary to change the ink volume from zone to zone. The ink is transferred from the screen roller to the printing plate by an ink form roller. With Anicolor 2, the ink density can be increased by activating the Anicolor Booster via the Prinect Press Center XL 2. This does away with the need to change the ink chamber in most cases, since both coated and uncoated substrates can now be processed with the same ink series. The larger range of color settings increases the flexibility when processing different substrates and inks. Optimized washup programs make fast ink changes even faster. The screen roller also rarely needs to be replaced. Makeready processes can be further reduced by selecting various ink shut-off programs.

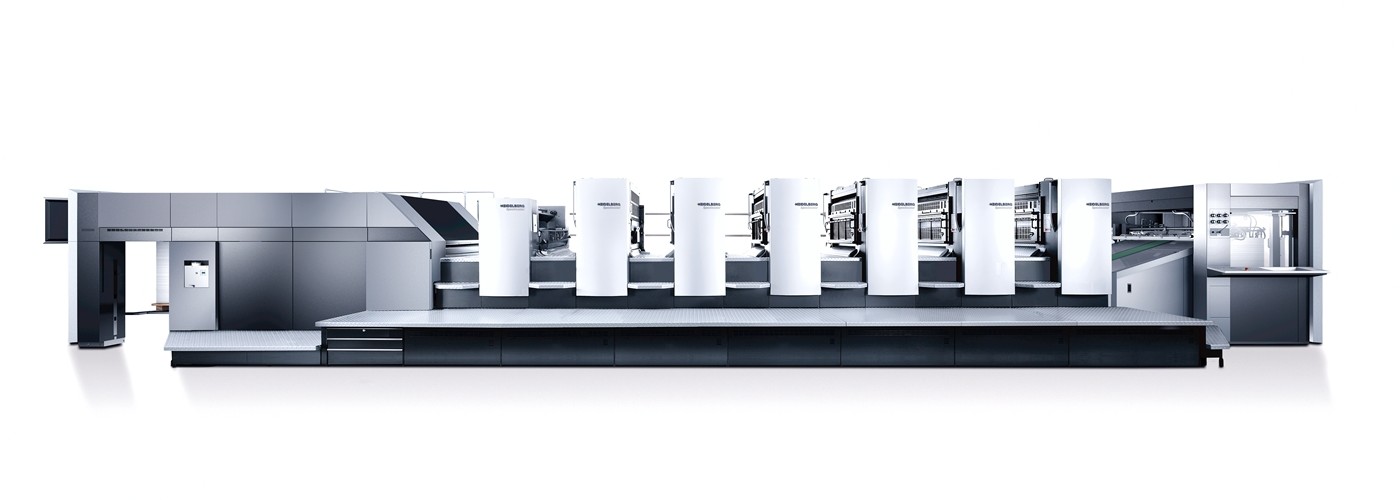

For small or large runs, a high level of finishing or standardized jobs – if you want to be economically successful in the world of industrial printing, you need the very latest technology. The Speedmaster XL 106 offers the most innovative solutions, tailored specifically to your requirements. For traditional commercial or packaging printing, for label printing or web-to-print, this press guarantees you maximum productivity combined with top efficiency and total ease of operation. The Speedmaster XL 106 has the highest level of automation on the market. Get the jump on industrial printing production of tomorrow with Push to Stop: for the first time in the history of offset printing, you can now change jobs fully automated – from the last to the first good sheet, right up to the start of production. The unique, job-oriented Intellistart 2 assistance system will revolutionize how you change jobs, with efficient job preparation and automatic generation of time-optimized job change programs.

When it comes to achieving maximum success, there can be no compromises. Take advantage of all the possibilities offered by large-format printing with our Speedmaster XL 145 and XL 162 – for top efficiency and maximum productivity combined with total ease of operation. In the area of commercial and packaging printing you benefit from innovative solutions specially tailored to your requirements, with particularly convenient operation. The high level of automation and the intelligent press control simplify all work steps and minimize your makeready times, energy consumption, and paper waste. Extremely fast job changes and tightly controlled, stable processes deliver maximum economy