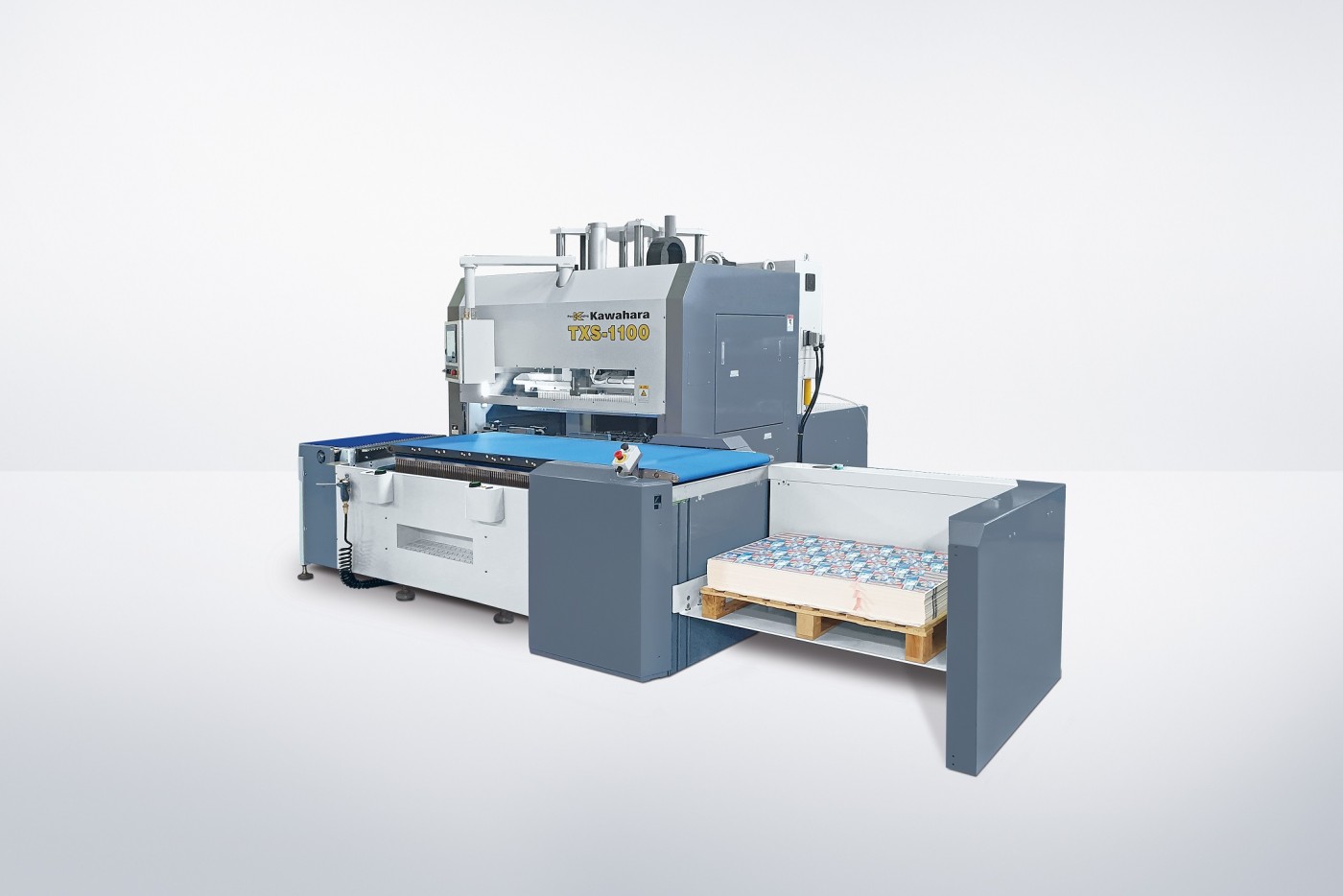

Kawahara blanking systems

One of the latent challenges in the global printing industry is the shortage of skilled workers, regardless of the production area. Production processes are becoming increasingly complex, while time pressure and requirements are increasing. Skilled workers who can keep up with the growing workload and the increasingly demanding processes are harder and harder to find. Added to this is the fact that particularly with manual activities, individual performance and motivation as well as knowledge and experience of the individual employees often lead to results of varying quality and thus predictability.

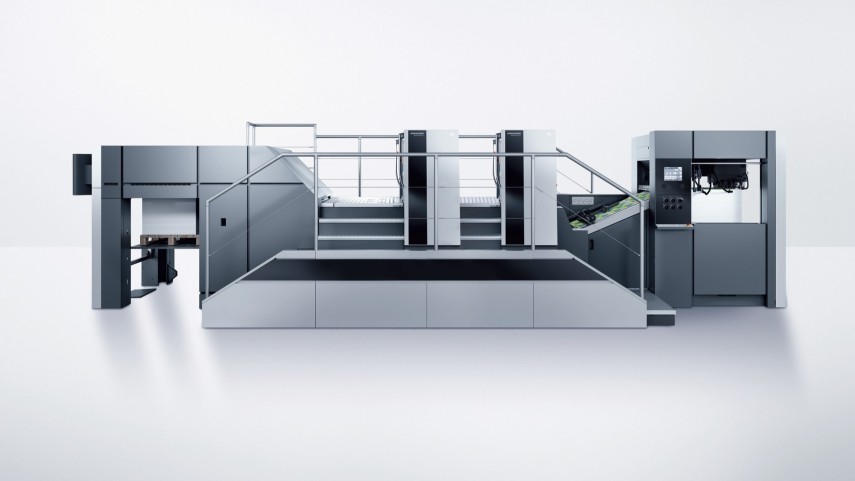

In addition, the high performance of modern printing presses, particularly in postpress where a lot of tasks are still done manually, necessitates a lot of workers. This applies in particular to the manual blanking of the die-cut individual blanks. What’s more, the potential of the machines, for example the Speedmaster XL 106-D rotary die cutter, cannot be fully exploited. Heidelberg therefore automated a further step in the production workflow by adding Kawahara postpress systems to its portfolio as part of a sales cooperation agreement.

Contact us for a tailored quote based on your specific requirements

Detailed Features

- Faster processing of pre-cut sheets

- Automated blanking replaces hand-stripping

- One-person operation

- Blanking without tools

- Inexpensive simple tooling

- Blanking cycle of 30 seconds for a pile of die-cut sheets up to 80 mm high

- Remote service connection

- Data transmission to Management Information System (MIS) possible

Order the product now and we will contact you within 24 hours.

Similar Products

You might also like these products